Our fields of competence

We develop technologies and products for lightweight structures. The focus lies in aircraft design, wind turbines, high-speed trains, automobile and research facilities.

Development of complex aircraft systems at the limit

Development of complex aircraft systems at the limit

Development of complex aircraft systems at the limit

We develop technologies and products for lightweight structures. The focus lies in aircraft design, wind turbines, high-speed trains, automobile and research facilities.

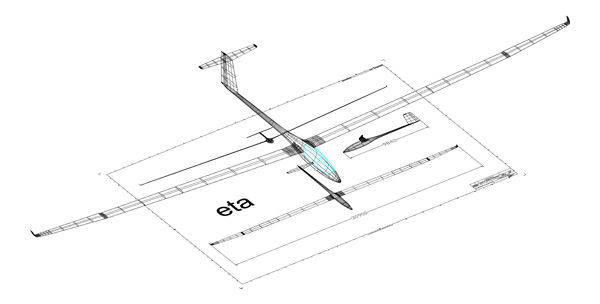

20 years ago, we developed the eta, since then the world’s biggest fully certified high-performance glider. Read about Hans-Werner Grosse, the great aviator who inspired the plane and passed away in February 2021 and also about eta’s remarkable flying capabilities in a feature of the Flyer Magazine (www.flyer.co.uk).

Today we use the eta prototype as an instrumented research aircraft. Listen to a presentation from our CEO, Dr. Reiner Kickert. The treasure chest of knowledge we gained from design and certification of eta as an elastic aircraft, together with our advances in methods, structures and systems, encouraged us in 2015 to start the design and prototyping of High-Altitude Platform Stations (HAPS). Our specific fully certifiable airframe technology overcomes airworthiness limitations for ultra-lightweight solar powered aircraft and also enables the design of hydrogen powered HAPS which surpass the communication capacities of today’s known Low Earth Orbit satellite constellations by multiple orders of magnitude.

While conceptual design work for a solar powered platform is currently underway at Leichtwerk, the prototype of a hydrogen powered HAPS is actually already in production. It features a very high communication capacity to serve up to 100.000 households per aircraft and provides in parallel ubiquitous nomadic mobile LTE/5G/6G communication to create a groundbreaking new level of area-wide connectivity – not even possible with terrestrial or space-based networks.Read more about our advanced project StratoStreamer.

Information systems need to be tailored to the world’s regional demands. Different system approaches are being used or emerging: Terrestrial tower, GEO and LEO satellites and HAPS. A viable world-wide solution has to be built on a sound business case, where cost, price and the market must match. We have to integrate the terrestrial, atmospheric and space-based technologies to meet actual customer demands. Read more about background information on the HAPS technology in general, how it can be tailored to the world’s demands and how it is to be integrated in terrestrial and space-based networks on haps-broadband.org.

With the quality assurance procedures of the aircraft production organisation, modern equipment and about 2400 sqm production floor, Leichtwerk AG covers the entire Aircraft Design process starting with Configuration Design and specific aerodynamic analyses.

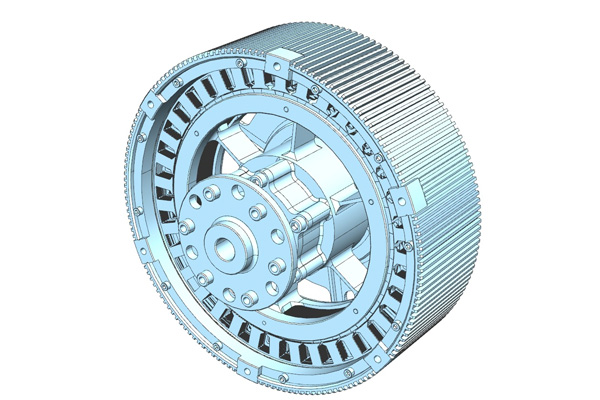

The development of technologies for electric flights enables new aircraft configuration like eVTOL or Long Endurance Aircraft fuelled by Hydrogen.

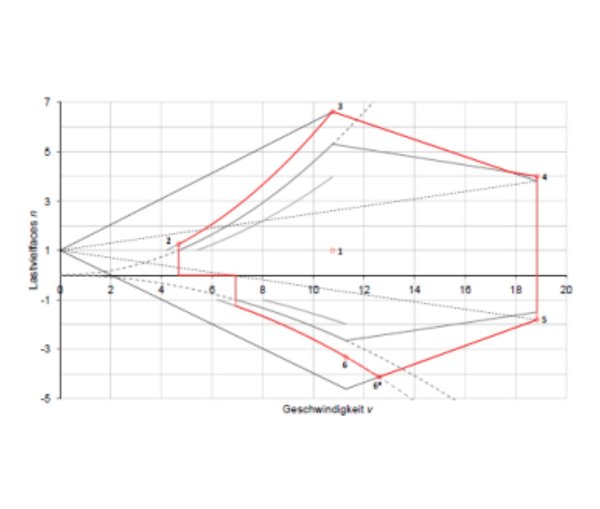

Our tool chain for aircraft load analysis takes moderate elasticity of the airframe into account. Load optimisation with aeroelastic tailoring is a stand.

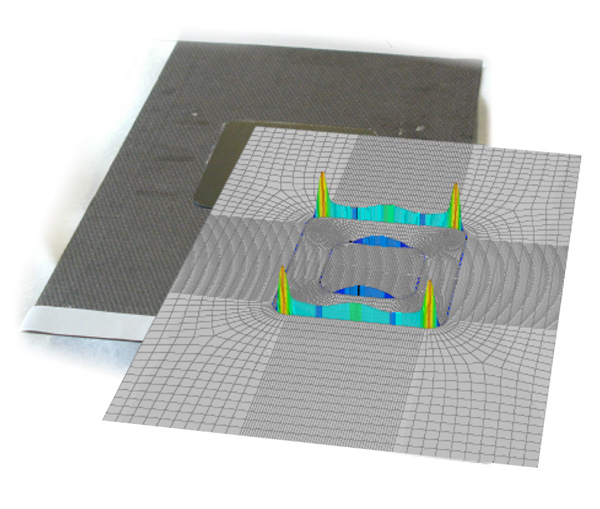

Leichtwerk AG excels in structural design. We have various validated in-house tools for composites, bondings and metallic structures under static and fatigue loads. Crack propagation, Wide Spread Fatigue Damage, de-bonding and other effects are standards for us.

For complex aircraft systems we have the capabilities to specify and accept complex airborne hard- and software.

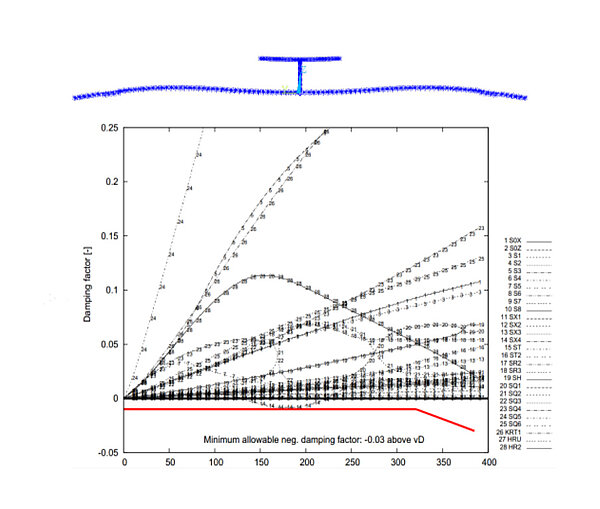

For aircraft certification, Leichtwerk AG offers ground vibration tests and aeroelastic analyses for assessing flutter hazards. A record of substantiation to this effect is required for many aircraft categories (according to Section 629 of the certification specifications) and must be performed before the maiden flight.

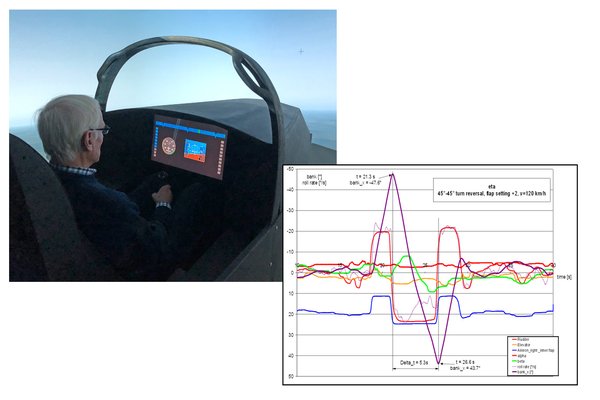

Flight dynamic modelling and control law design with Matlab™ and Scade™, Hardware in the Loop testing, simulation and in-flight parameter identification are key for the design of tomorrow’s unmanned aircraft systems.

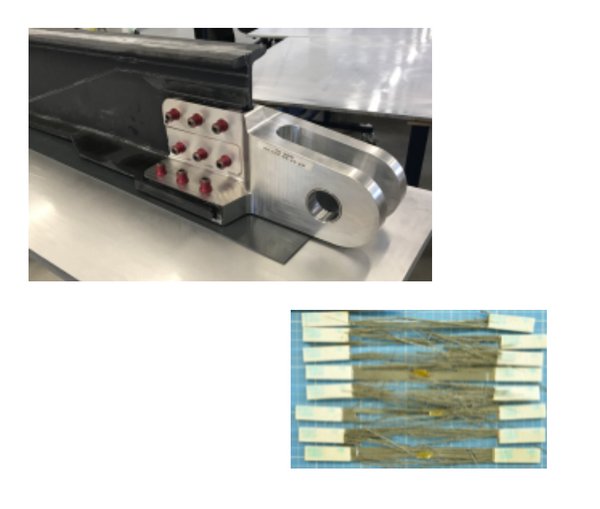

Our prototyping workshop works with prepregs as well as with resin infusion techniques. In new projects we develop the structure substantiation pyramid from coupon level to airframe tests.

With our EASA DOA 21J.332 we have the necessary processes for Design Assurance in place.

All information to our use of Methods and Code Development

Prototyping is an essential part of the entire aircraft design process.

Flight Testing is an inherent capability for successful Aircraft design.